A Detailed Description of the Seneca Grain Cleaning Process

Rotary Precleaner

Rotary Precleaner

We have the option of running any incoming grain through a rotary precleaner with interchangeable screens to remove any impurities of vastly different size or density to the product. By reducing the workload on machines downstream we can achieve better results at a higher speed. Additionally, this machine is located outside allowing us to keep a large amount of dust out of the main processing area. This keeps the facility cleaner and makes for a more pleasant working environment.

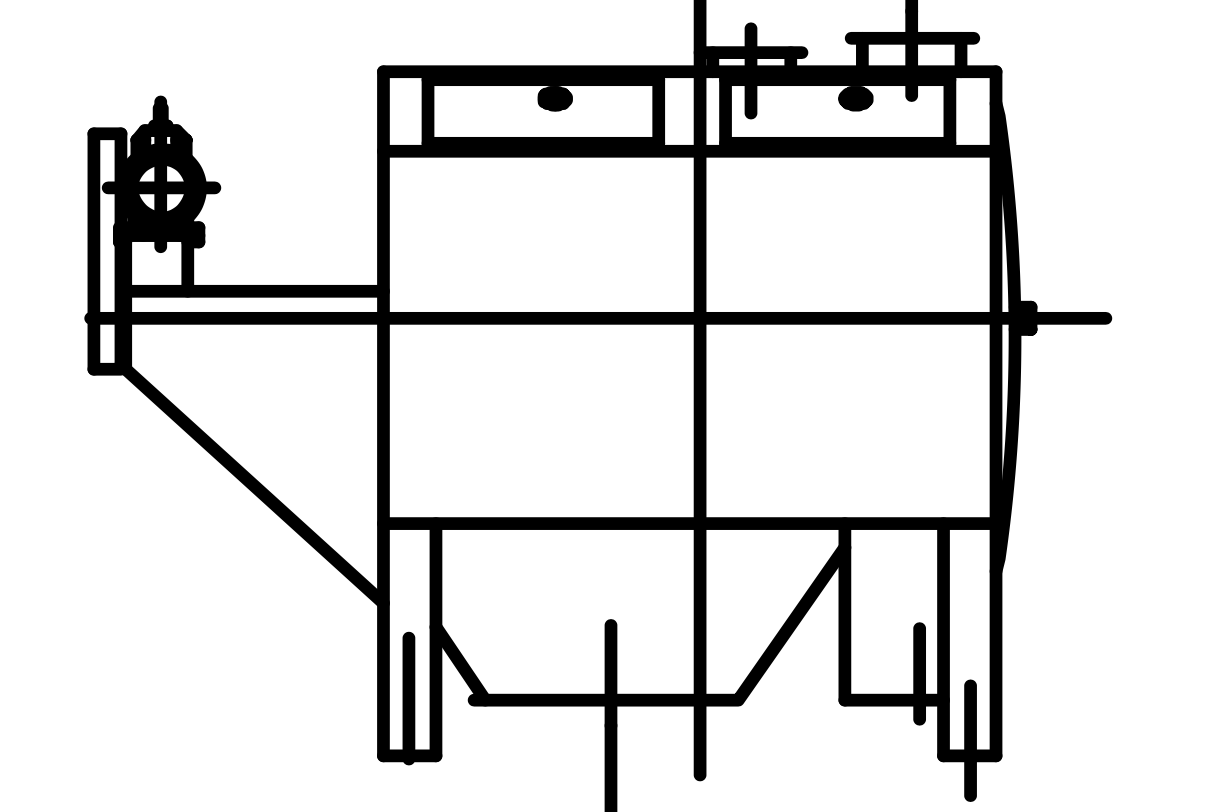

Airstream Cleaner

Airstream Cleaner

An Airstream Cleaner uses a combination of Air Currents, Vibration, and Screen Size to remove impurities that are much lighter, larger, or smaller than the desired grain or pulse. The product first passes through the Aspirator, in the aspirator it is spread out to the full width of the machine and passed through an updraft. We can adjust the strength of the updraft to determine how much is removed here, this is used to remove light impurities. Next the grain or pulse passes through or over up to 4 layers of screens. We keep a large selection of screens to accommodate a wide range of crops and buy new sizes as the need arises. Once our screens are selected, we use the vibration frequency to control how quickly the product passes across the screens.

Destoner

Destoner

A Destoner uses a combination of Air Pressure and Vibration to separate dense impurities such as pebbles from desirable product. The product is spread out onto a vibrating inclined perforated table with air pressure beneath. The air pressure encourages material to slide down the incline while the vibration works material up. When air pressure and vibration are properly balanced, pebbles will separate from the good material and subsequently are removed from the top of the table.

Magnetic Separator

Magnetic Separator

The Magnetic Separator uses a series of powerful magnets to remove ferrous contaminants. That generally will include any nuts, bolts, or other stray iron that may have been present in the field or in harvest or handling equipment. Additionally, this machine will remove any lumps of soil that escaped the airstream because most soil contains more iron than beans or grain.

Gravity Table

Gravity Table

Like the Destoner, the Gravity Table uses a combination of Air Pressure and Vibration to sort based on density. Unlike the Destoner, the purpose of the Gravity Table is to remove product that is less than the desired density. This generally includes immature or damaged beans or grain.

Dry Polisher

Dry Polisher

The Polisher uses a set of fabric brushes spinning inside a stainless steel screen to remove dust or dirt that is stuck to the seed coat. This creates a good deal of dust which is removed by a large volume dust collection system. Many polishers in the industry use a little bit of mineral or vegetable oil to make the surface of a bean shine which can cause allergen concerns. Our polisher is a dry polisher using friction alone to shine up our beans.

Optical Sorter

Optical Sorter

The Optical Sorter uses 12 high speed cameras to inspect every bean or kernel of grain and compare them to a set of images that the operator defines as “good” or “bad”. This allows us to remove the vast majority of any remaining contaminants that our other machinery was unable to get out.

Packing Machine

Packing Machine

Our Packing Machine allows us to bag in 25 or 50lb paper or woven poly bags. With 2 operators we can bag at up to 5 tons per hour.